Thursday, September 8, 2022

Zinsco Electrical Panelboards

What you should do if you Have an old Zinsco electrical panel board

Zinsco was a producer of electrical switchboards and circuit breakers. the company was founded by Emile Zinsmeyer in the early 1930s.

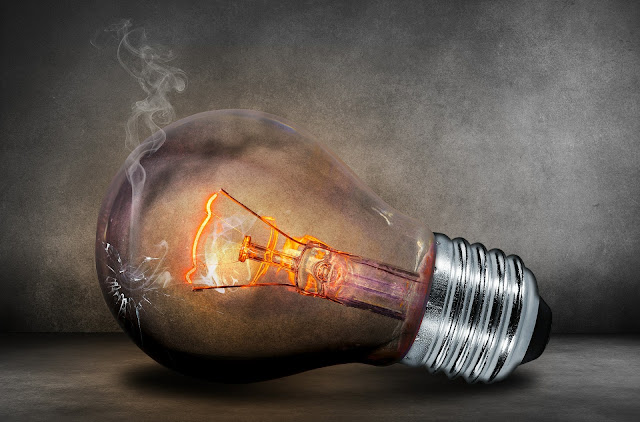

At one time Zinsco Electrical panel boards were usually introduced in homes in specific pieces of the country. As time has elapsed, inspectors and home auditors have found that specific Zinsco boards frequently can neglect to work and may pass on homes and property holders in danger to both fire and electrical shock. These boards can turn out great for a really long time, however as homes have expanded energy requests, these boards might overheat and partitions of it soften.

In this present circumstance, in the event that a breaker melts to the power busbar of the board and can never again satisfactorily trip if there should be an occurrence of an overcurrent or shortcircuit conditions, an outrageous measure of force from the external electrical stock floods into a panel board and circuits. When that occurs, it can't be halted or turned down physically. Power will consume until it runs out of fuel or the wires dissolve. The board could overheat and burst into flames, really hurting property and its people.

Zinsco Electrical panel boards might appear to turn out appropriately for quite a long time. Yet, specialists caution that these boards might introduce various issues and even dangers if and when they fizzle. As a matter of fact, one master cautions that as numerous as 20% of all Zinsco circuit breakers could not trip in light of an overcurrent or short circuit causing what is happening.

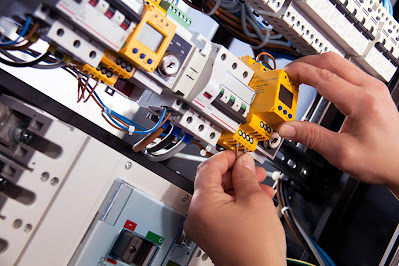

Issues with specific Zinsco Electrical panel boards shouldn't be visible to the unaided eye. Indeed, even after the front of Zinsco boards has been eliminated, everything can appear to be in fine working request. After investigating its parts, electrical technicians find that breakers can't be taken out from the power bus bar. They've welded together, which shows that the breakers have dissolved. In that condition, a breaker would not be able to trip and might be permitting a risky measure of power into the home! This could prompt a possible fire.

Kindly, don't endeavor to eliminate breakers from your own board to check whether they've dissolved. Just authorized electrician to do it.

Specialists Have Distinguished Two Significant Reasons

Specialists report that Zinsco electrical switchboards might have two significant issues that could represent a risk:

1.) Zinsco boards may not meet the present standards. (UL/NEC)

2.) Zinsco boards might have design issues.

Certain parts of the board contain aluminum.

The connection between the breakers and the bus bar is in many cases not strong.

The busbar quality issues

Circuit breaker faults

The electrical switchboard is one of the main parts of a home's electrical framework. The board safeguards homes from power floods and other potential perils. With customary support by an authorized electrical expert, specialists say that the present electrical boards can work appropriately and safeguard homes for quite some time or more. You can also contact an authorized electrical engineer in your space for an examination.

Electrical Junction Boxes Explained

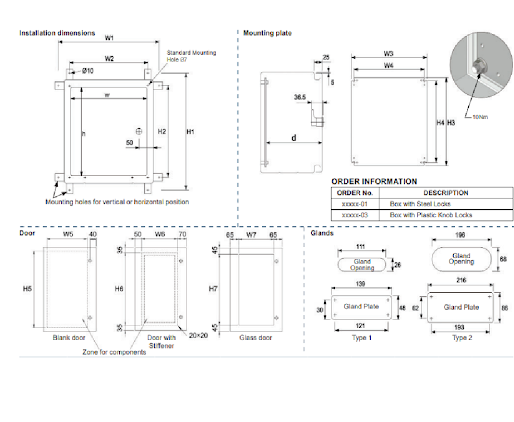

Electrical Junction boxes shield the electrical connections from the weather, in addition to protecting humans or animals from accidental electrical shocks. A junction box (also called "jbox") is a smaller steel or polycarbonate enclosure housing that is mainly used for electrical terminal connections.

A small metal or plastic junction box might type a part of a jbox electrical passage or thermoplastic-sheathed cable (TPS) wiring system during a building. If designed for surface mounting, it's used principally in ceilings, below floors, or hidden behind Associate in Nursing access panels—particularly in domestic or industrial buildings. Associate in Nursing applicable sort is also buried within the plaster of a wall (although full concealment is not any longer allowed by trendy codes and standards) or solid into concrete—with solely the duvet visible.

It generally includes intrinsic terminals for the change of integrity of wires.

A similar, sometimes wall mounted, instrumentality used principally to accommodate switches, sockets, and therefore the associated connecting wiring is named a pattress.

The term junction box can also be used for bigger items.

Junction box types are used for circuit protection systems wherever circuit integrity has got to be provided, such as for emergency lighting or emergency power lines, or the wiring between a setup and an impression area. In such an Associate in electrical installation, the hearth proofing around the incoming or outgoing cables should even be extended to the junction box to forestall short circuits within the box due to accidental fire.

Electrical Panel Clearance Requirements

Electrical Panel Clearance Requirements (NEC)

For low voltage electrical panel installation or streamlining, it's important to make sure that there's sufficient space or clearance of room around the electrical panel for the electrician to safely work. This is why NEC 110.26 has put a demand that all indoor electrical panels have a minimum clearance of room from the front of the panel to the nearest place (this could be a wall, a machine, or any other fixed object). In addition, they bear that there's at least a 0.9-meter height from the panel to the electrical room ceiling.

These conditions are in place for several reasons. First, anyone who needs to work in or around the panel needs enough room to maneuver around without accidentally touching cables, combers, or other objects in the panel. In addition, having at least three bases in the room will ensure that nothing is going to get stuck in the area while trying to work. In the event that someone is electrocuted or else injured, the three bases of concurrence will allow croakers or other exigency askers to get in and help the existent.

There are also some simple practical reasons why having three bases of concurrence as a minimum is a good idea. This important room will allow electricians to bring in the tools that they need to work in the area safely. NES wants to make sure that anyone working in the area around an electrical panel is suitable to do so with as little threat as possible. These regulations are also generally going to apply to industrial or commercial electrical panels.

Clearance around an Indoor electrical panel (National Electric Code110.26):

Clearance around an Indoor electrical panel (NEC 110.26): | |

| Description of Clearance | Distance (min) |

| Left to Right the minimum clearance | 0.9 Meter (3 Ft) |

| Distance between Panel and wall | 1.0 Meter |

| Distance between Panel and Ceiling | 0.9 Meter |

| Clear Height in front of Panel>480V | 2.0 Meter |

| Clear Height in front of Panel <480V | 0.9 Meter (3 Ft) |

| Clearance When Facing Other Electrical Panels < 480V | 0.9 Meter (3 Ft) |

| The width of the working space in front of the Panel | The width of the Panel or 0.762 Meters which is Greater. |

| Headroom of working spaces for panel boards (Up to 200Amp) | Up to 2 Meter |

| Headroom of working spaces for panel boards (More than 200Amp &Panel height is maxing 2 Meters) | Up to 2 Meters ( If Panel height is maxed 2 Meters) |

| Headroom of working spaces for panel boards (More than 200Amp &Panel height is more than 2 Meters) | If the Panel height is more than 2 Meters then clearance should not less than the panel Height |

| Entrance For Panel (More than 1200 Amp and over 1.8 m Wide) | One entrance is required for working space (Not less than 610 mm wide and 2.0 m high ) |

| Personal Door For Panel (More than 1200 Amp) | Personnel door(s) intended for entrance to and egress from the working space less than 7.6 m from the nearest edge of the working space |

| Dedicated Electrical Space. | Required Space is the width and depth of the Panel and extending from the floor to a height of 1.8 m (6 ft) above the equipment or to the structural ceiling, whichever is lower |

| The door(s) shall open in the direction of egress and be equipped with panic bars, pressure plates, or other devices that are normally latched but open under simple pressure | |

| the workspace shall permit at least a 90-degree opening of equipment doors or hinged panels |

(Extracted from NEC 110.26)

Wednesday, September 7, 2022

Why You Should do Electrical Panel Upgrade if You Have an Old Panel

When to do your electrical panel upgrade

Electric power failure?

Have you ever used a new appliance and had the whole house experience an electric power failure? If you've been living in the same home for a time, electric power failure might be a normal circumstance. For those in a rental contract, electric power failure might also be familiar if you stay in an old house. So, what is the deal with the annoying electric power failure? The electric switchboard may be a problem, and you might need to upgrade the electrical panel. This composition will show why you might need an electric panel upgrade and when you should do it.

Vibrating Lights

Vibrating lights are a reason for the electrical panel upgrade. However, if this is not scary enough for you, we'll tell you why.

Breezy lights are a derivate of defective wiring. Other than problems with the lights, bad wiring will beget a burnt smell and can generate shocks when touching certain appliances, similar to broilers or laptops. You'll see some marks and sparks on current outlets or sockets in your home if you feel warm in the electric panel it's another sign.

Tripping panel board Miniature Circuit Breakers

You've installed a new air conditioner, and your circuit combers trip each time you turn on the air conditioner. So, what is the problem? Circuit combers trip and shut off electrical inflow because a circuit is overfilled.

The reality is that electric panels need to be upgraded every 25- 40years. However, it will not be suitable to handle new appliances, If your home still uses an old electric panel.

This is because an old electric panel cannot handle too necessary electricity.

These days, ultramodern homes run on new and advanced appliances. With an ancient electric panel, your home may witness electric power failure daily. If this happens, it's time to change your electric panel.

Power Strip operation

Are you using other power strips to charge bias each over your home? Houses have limited wall sockets, and using many power strips means using different electricity than your electric panel can handle.

Twenty times agone, two or three wall sockets were enough for a home. These days, we need different sockets due to the overflowing demand for electricity.

Still, it's undoubtedly time to upgrade your electric panel, If you have a bunch of extension cords and power strips over the home. Click then to learn more about the peril of power strips and some tips to cover your family and home.

Your Home Safety Tips

Besides upgrading your home's electricity capability, you'll be doing your home a favor by icing that it's safe to live in. Your home will be safer from fires and other electrical disasters by being prepared and ensuring your electrical panel upgrade.

Another thing is that if you have upgraded an electric panel, it will increase your home's value. For those planning to move, upgrading your electric forum will be a selling point for implicit buyers because they won't need to upgrade it.

Still, you can hire a professional to check it, If you are doubtful whether your home needs an electric panel upgrade. They can also help you determine what steps to take to ensure your electric panel is in good shape. They might suggest you change the cables or upgrade the entire forum. this is one of the best investments for your old home

Read the extra article about the electrical panel upgrade cost

Electrical Switchboard Manufacturers in Sydney

Local switchboard manufacturers in Sydney NSW Australia

Custom Build Switchboard Fabricators, Switchboard builders & Modular Switchboard Distributors NSW

CNW Electrical Wholesale

Alexandria New South Wale

K E Brown Electrical Switchboards

Warriewood NSW, Australia

OSSI Electrical Pty Ltd

NSW

Relec Switchboards Pty Ltd.

Asquith NSW, Australia

Chadwick Switchboards

Wetherill Park NSW, Australia

MPE Custom Switchboards

Guildford NSW, Australia

Southern Cross Switchboards

Silverwater NSW, Australia

Reagle Switchboards Pty Ltd.

Silverwater NSW, Australia

Ausboard PTY Ltd.

Marrickville NSW, Australia

Trivantage Manufacturing

Arndell Park NSW, Australia

Blacktown City Switchboards Pty LTD

Kings Park NSW, Australia

+61 2 9831 2530

JBM Power Pty Ltd

Minto NSW, Australia

Hi Switch

Riverstone NSW, Australia

Aussie Electrical Services

NSW

Norselec

Kurnell NSW, Australia

Southern Cross Switchboards

Silverwater NSW, Australia

Fuji SMBE Macquarie Pty Ltd

KJE Electric

Wetherill Park NSW, Australia

Bovara Switchboards Solutions

Huntingwood NSW, Australia

Tabulec Switchgear Pty Ltd

Smithfield NSW, Australia

+61 2 9757 4191

SMS Electrical Products Pty Ltd

Girraween NSW, Australia

CUBE ELECTRICAL INDUSTRIES PTY LTD

Penrith NSW, Australia

A-Force switchboards PTY LTD

Caringbah NSW, Australia

+61 2 9526 8944

Monday, September 5, 2022

Cost of Replacing an Electrical Panelboard

Cost of Replacing an Electrical Panelboard

If you want an electrical panel to improve, you'll be thinking about how a good deal it'll fee. The fact is that numerous elements decide the charge of an Electrical switchboard alternative, so the solution isn't straightforward. This publishes breaks down what you want to recognize approximately those expenses and the way to put together several electric alternative expenses.

Let me tell Electric Panel and the Fuse Box. Before we get into expenses, many human beings are regularly harassed with what an electric powered panel (or circuit breaker) is and the way it differs from the fuse container. So let's get matters directly first.

The Electrical switchboard is the principal container for your private home or office that controls all of its electrical wiring and electricity. It's commonly positioned in a garage, basement, or application room. When you open the door in your electric panel, you'll see rows of breakers or switches which can manipulate or cut-off power to a positive circuit. These circuits are regularly what deliver the diverse regions of your private home or office with electricity—that's why you'll regularly see them labeled "dressing room," "kitchen," "downstairs bathroom," etc.

When an electrical surge happens in such a circuit, it'll "trip the breaker," and that transfer will pop up, cutting-off voltage to that precise circuit. These may be reset via way of means of flipping their lower back on, and in case you reset the breaker, however not anything comes lower back on, it can be a brief circuit, which calls for an electrician, or it can be a sizable outage, and you could take a look at together along with your nearby electric company. The fuse container, on the alternative hand, is generally cited as "the breaker container," maybe interior, both an electric powered panel or cut loose it outside. It incorporates fuses that seem like little bulbs. When a fuse reviews a voltage overload, just like the breakers, it'll certainly soften the filament, which reasons the fuse to want to get replaced. This is what's referred to as a blown fuse. It's a clean restore and might get you to lower back up and stroll in minutes. It s Needs an Electrical Panel Upgrade. Your Electrical switchboards are probably seriously outdated, in particular, if you got an older domestic panelboard. They can last as long as forty years or greater, relying on many elements. However, something over 25 years antique will be taken into consideration as risky and must be monitored intently or serviced and changed to make certain it really works properly (and safely).

Signs it's time to upgrade your electric powered panels include: It's older than 25 years antique You revel in often tripped breakers You want/need to put in greater stores It nonetheless makes use of fuses vs. circuit breakers The panel feels warm to the touch/is overheating The electric powered panel is rusted or broken You listen unusual noises coming from the panel You scent burning or see smoke—a hundred% name an electrician proper away The panel has been glaringly broken or is coming lose You set up a brand new, big appliance You note lighting fixtures flickering while you switch on different home equipment or devices These are all legitimate motives to get your electric panel serviced and/or upgraded. It's vital to have one who can manage the extent of electricity required for your private home and additionally meets up-to-date enterprise standards.

The common fee of an Electrical panel upgrades cost alternative is between $900 and $3000. This variety is a touch big as it relies upon what number of amps your property needs, and additionally, in case you are changing a current panel or putting in one logo new. Most homes use between 100 and 200 amps, which measures the extent of power flowing thru electric wires. Old houses with minimum stores and electric home equipment (like HVAC) would possibly handiest use 30-forty amps, even as a logo new, big domestic with modern-day electric paintings would possibly deplete to four hundred amps. A trendy 2 hundred amp domestic, though, must fee around $1,500 to improve your electric-powered panel. So, in case you're trying to improve your Electrical switchboard and want greater stores or areas for a bigger domestic, assume to spend between $900 and $2,000. Older houses might cost a little greater in reality due to the fact the machine itself may be a large number to navigate, and electricians would possibly locate they want to update greater than simply the electrical panel itself. The fee to improve to a hundred amps: is $800-$1200. The fee to improve to 2 hundred amps: $1,2 hundred-$1,600 The fee to improve to four hundred amps: $1,800-$4,000. If your panel is simply too antique to improve otherwise, you need a completely new machine with renovations, and your expenses will cross up. The fee of a brand new hundred amp machine: is $1,200-$1,600 The fee of a brand new 2 hundred amp machine: is $1,600-$2,600. The fee of a brand new four hundred amp machine: $2,000-$4,000+

The fee of upgrading your electric powered panel is really at the better end; however, the expenses of greater huge damage, or maybe a fire, are ways greater. So to maintain your private home safe and efficient and to mitigate risk, recollect upgrading your panels earlier than something happens. The Cost to Replace Your Panelboard with a Circuit Breaker There are a few different enhancements to recollect when you have an older domestic or are increasing your private home that guides your new Electrical switchboard and make certain your private home's whole electric machine works in tandem together. Replacing your fuse container with a circuit breaker is one of these matters to recollect. Fuse containers are more difficult to manipulate and mightn't manage pretty the quantity of power current houses use anymore.

Pros of a Fuse Box Easy to DIY—house owners can update their personal fuses, are Cheaper than a circuit breaker, and are more touchy to greater currents. Cons of a Fuse Box Always has to get replaced while the circuit is tripped. Can't manage current-day home equipment—they want greater current

Pros of a Circuit Breaker Simple to reset while it receives tripped Compatible with current-day home equipment and power needs Very user-pleasant and safe Compatible with GFCI Cons of a Circuit Breaker Less touchy to greater currents More luxurious restore and alternative Not DIY-pleasant—have to get replaced via way of means of an electrician

Why Upgrading Your Electric Panel is Worth the Cost Your electric-powered panel is regularly out of sight and out of mind—sitting someplace in your basement wherein you don't consider it till the circuit journeys while a person makes use of the microwave.

Tuesday, January 5, 2021

Plastic Enclosure Boxes For Electrical Apparatus

Polycarbonate plastic walled in areas are for the most part more affordable than metal nooks and have amazing effect opposition. Polycarbonate is additionally unfathomably adaptable and reasonable for a wide scope of indoor and outside applications.

Due to their ease, polycarbonate fenced in areas are ordinarily utilized in work area hardware and electrical instruments related with the IT business.

HAMMOND MANUFACTURING

https://www.hammfg.com/electronics/small-case/plastic

DUINO.LK

https://www.duino.lk/Waterproof-Plastic-ABS-Enclosure

POLYCASE

Sunday, November 1, 2020

NEMA 12 Enclosures (For North American Markets)

NEMA 12 Enclosures (For North American Markets)

NEMA 12 enclosures are meant in particular for indoor commercial, manufacturing, and machining programs. These steel enclosures will defend in opposition to dust, dust, and dripping non-corrosive beverages, oil and lubricants. Our adherence to NEMA requirements will provide you with a nice enclosure for any industrial utility. We produce some of the enclosure types in aluminum, carbon steel, and stainless steel brought quickly at aggressive charges.

NEMA 12 Characteristics:

# Primarily for industrial indoor use

# Protection against dirt, falling dust, fibers, and lint

# Protection from dripping water and different noncorrosive drinks

# Resistant to harm from outside condensation of noncorrosive liquids

# Doors with oil-resistant gaskets

# Available with pre-punched holes, cutouts, raise-off hinges, insulation, latches, or locks

# NEMA Enclosures manufactures satisfactory custom and trendy NEMA-rated enclosures.

Friday, October 16, 2020

Wednesday, October 14, 2020

PLC & DCS differences

PLC or programmable logic controlleris a robust computer used to automate processes.A DCS or distributed control system is similar to a PLC that it has robust computer controllers

However, DCS contains multiple autonomous controllers

distributed throughout the system,

It is also used to automate processes.

You may have read it and said, "So what's the difference?"

To answer this question,

we have to go back more than 40 years.

After several years in a corner design office,

this guy Dick Morley quit his job

after asking his employer to allow him to work on Saturdays instead of Fridays,

who refused.

You see, Mr. Morley loved skiing, but he found that the weekends were too crowded for his tastes.

Due to financial obligations and the like,

Mr. Morley and a friend formed Bedford Associates

where they wrote sentences,

for local tool companies, which wanted to evolve into the new stage of solid state production.

These proposals used small computers,

seemed to be repetitive in nature,

and from one project to another,

there were many similarities.

Eventually Mr. Morley got bored of writing proposals,

due to its repetitive nature,

and began to wonder if he could create an auditor who could handle these day-to-day tasks.

In fact, during his dismissal, Mr. Morley created a blueprint

for a proposed programmable controller and got it on his team.

They started designing the programmable controller.

After finding financial support,

the company, Modicon was created.

Without Modicon knowledge and during the design phase of the programmable controller,

a man from GM had presented a newspaper,

a request, for a solid state controller that will make the plants more reliable and durable,

which would also replace wired relay systems

spread to the manufacturing industry.

As the story goes, some time later,

GM is hearing about the work being done at Modicon

and final contracts with them for the purchase of over $ 1,000,000 in PLC

(then, auditors were called programmable auditors

and the "Logic" section of the current name

was not added until the dawn of personal computers or computers).

Modicon was later baptized and quickly became a business.

The name has persisted in a few acquisitions,

the latest and current is Schneider Electric.

In the beginning, the PLC was mainly used for discrete controls.

Ultimately, the big market from GM for the replacement of wired relay systems.

The programming of the PLCs was mainly in the logic of the ladder,

which is a form that looks a lot like a schematic.

The PLC received device information from the field,

solved the logic and then activated the outputs to produce the desired result.

In essence, the PLC was invented to perform repetitive tasks in a reliable and robust manner.

As for DCS, around 1975 some companies released a version of a DCS.

Basically, the creation of a DCS system was due to the increasing use of microcomputers.

There were other computer-based systems in the industry

from the late 1950s, but had limited capabilities

for scalability, durability and safety.

There were many benefits to a DCS, but one of the main draws

was that an entire factory could be connected through proprietary communications

and is controlled by a distributed system.

For example, suppose you had a plant that made an ice cream sandwich.

The factory will have a production line for ice cream

and one of the standalone inspectors would process the batch of ice cream.

After the ice cream batch is complete,

Another standalone controller can process the freezing of this ice cream.

Another controller can process the cookie batch,

while another may oversee the baking process.

With several autonomous auditors,

if one auditor failed, it would affect only this process and not all the others,

leading to a powerful system that virtually eliminated all plant failure.

DCS was really good at autonomous control of single or multiple processes.

Another important benefit of DCS was integrated monitoring

and a control system similar to current SCADA systems.

The reason it's a big benefit is that the whole label base is there,

has already been set up to control the process,

available for use on monitoring and control screens.

DCS also had operating block programming.

Program block operation, if you are not familiar with,

is a section or multiple lines of code behind a single interface.

This interface can do something like operate the manual

and automatic valve operation.

Operation block programming saves a lot of time and unnecessary programming.

In fact, the difference 40 years ago was significant

and if you had a large factory with continuous processes,

you would probably have chosen a DCS.

In today's industries, DCS and PLC are quite similar,

storage for integrated monitoring and control.

With open source communications, fiber optics,

Ethernet and the like, many PLCs can now communicate with each other

and be autonomous PLCs communicating over the network to other autonomous controllers.

This wide communication would allow the control of individual or multiple processes

from one PLC to communicate with another PLC.

See the example of an ice cream sandwich.

PLC-A could process ice cream.

When the batch is completed,

The PLC-A would communicate with the PLC-B that the process was complete

and PLC-B could then start the freezing process.

You can see it with today's technologies,

a wide and robust PLC system could do almost the same thing that DCS can do.

One advantage of DCS is the installation cost.

This advantage arises due to the position of the autonomous controller

in the process may be close to pulling large sections of I / O cables in an installation.

Another advantage is the integrated monitoring and control system.

One of the disadvantages of DCS is the lack of developers

who have some experience with a DCS.

Most flooring technicians are familiar with ladder programming

However, DCS developers and technicians

usually need more specialized experience in database operations

as well as computer-related networking knowledge.

Due to specialized training,

DCS developers are a little harder to find.

Speaking of advantages, today's PLC systems can have almost the same as DCS,

excluding supervisory control and data acquisition (SCADA).

With PLC system (multiple PLCs in factory structure),

you need to set up the monitoring and control system.

The entire DCS database would be available to set up the monitoring and system,

PLC systems individual PLC databases must be created in SCADA system software.

There are more developers available for rent in the PLC arena

and with new programming languages such as blockchain,

sequential operation, etc., the advantage of operating block programming is no longer exclusive to DCS.

This saves development time when planning a PLC.

As you can tell, there are potential advantages and disadvantages to both systems.

The subtraction is that with today's technologies,

Each system can control an entire factory.

Which system will be chosen will probably have the advantages

and disadvantages, as well as the cost of the system.

In summary, DCS has standalone controllers scattered throughout the installation.

If one controller fails, the whole factory is not necessarily affected.

It also has on-board control and control

which saves development time.

A single PLC is a single point of failure.

You certainly would not want to control an entire factory with a single PLC

however; a connected PLC system can have almost the same safety and durability as a DCS.

.jpg)

.jpg)