When building IoT devices or Raspberry Pi projects, choosing the right housing can make or break your creation. Small Enclosures for IoT & Raspberry Pi need to protect delicate electronics while maintaining accessibility for modifications and repairs. Whether you're creating a weather station, home automation controller, or industrial sensor. the enclosure you select will determine your project's longevity and reliability.

Finding the perfect balance between protection, size, and functionality isn't always straightforward. This comprehensive guide examines the best small enclosures available today. helping you make an informed decision for your next electronics project.

Why Enclosure Selection Matters for IoT Projects

Your IoT device's enclosure serves as the first line of defense against environmental hazards. Dust, moisture, temperature fluctuations, and physical impact can destroy unprotected electronics within hours of deployment. Small enclosures for IoT projects must provide adequate protection while allowing necessary connections and heat dissipation.

Beyond protection, the right enclosure enhances your project's professional appearance and user experience. A well-chosen case can transform a breadboard prototype into a market-ready product, while poor enclosure selection can doom even the most innovative design.

Top Small Enclosures for IoT Projects

Weatherproof IP65-Rated Cases

For outdoor IoT applications, weatherproof enclosures provide essential protection against rain, snow, and dust. These small enclosures for IoT projects typically feature rubber gaskets, cable glands, and corrosion-resistant materials.

The Hammond 1554 series offers excellent value with its polycarbonate construction and multiple size options. These enclosures include pre-molded mounting bosses that perfectly accommodate Raspberry Pi boards and similar single-board computers. The transparent lid allows visual inspection of status LEDs without opening the case.

Bud Industries' NEMA-rated enclosures provide superior protection for harsh environments. Their aluminum construction offers better heat dissipation than plastic alternatives, crucial for power-hungry IoT devices. The powder-coated finish resists corrosion while maintaining a professional appearance.

Compact Desktop Enclosures

Indoor IoT projects benefit from smaller, aesthetically pleasing enclosures that blend into home or office environments. These cases prioritize easy access and cable management over weather resistance.

The OKW Minitec series combines compact dimensions with excellent build quality. These small enclosures for IoT projects feature snap-together assembly, eliminating the need for screws while maintaining secure closure. The ribbed design provides additional structural strength and heat dissipation surface area.

Serpac's plastic enclosures offer remarkable versatility with their modular design. Multiple cases can be stacked or mounted side-by-side, perfect for expandable IoT systems. The wide variety of available colors helps with device identification in multi-sensor installations.

Clear Polycarbonate Options

Transparent enclosures allow visual monitoring of your IoT device's operation while providing protection from dust and accidental contact. These cases work particularly well during development phases when frequent modifications are necessary.

The Polycase QP series provides crystal-clear visibility with excellent impact resistance. These small enclosures for IoT projects include removable mounting feet and multiple knockout options for custom cable routing. The optical clarity remains unchanged even after extended UV exposure.

Essential Features to Consider

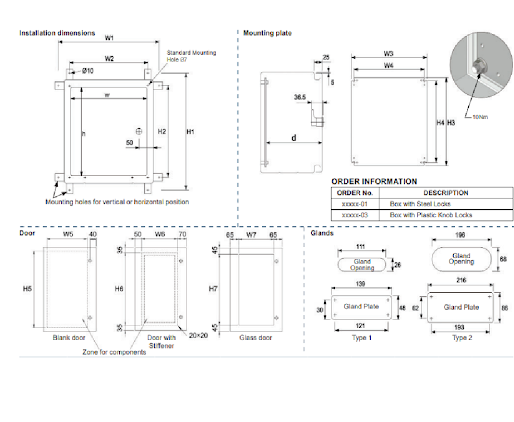

Size and Internal Layout

Measuring your components accurately prevents costly mistakes. Allow extra space for heat dissipation, cable routing, and future modifications. Many makers underestimate the space required for proper wire management, leading to overcrowded enclosures that trap heat and complicate troubleshooting.

Cable Management Solutions

Quality enclosures provide multiple options for cable entry and exit. Cable glands create weatherproof seals for outdoor applications, while knockout panels offer flexibility for custom installations. Consider both current and future connectivity requirements when evaluating cable management features.

Mounting Options

Your IoT device's deployment location determines necessary mounting features. Wall-mount enclosures save space in cramped installations, while panel-mount options integrate seamlessly into existing equipment. DIN rail compatibility proves valuable for industrial applications.

Heat Dissipation

Electronics generate heat during operation, and small enclosures can quickly become thermal bottlenecks. Ventilation slots, heat sink mounting provisions, and thermally conductive materials help maintain safe operating temperatures. Fanless designs reduce complexity but require careful thermal planning.

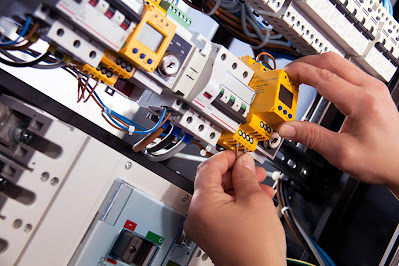

Installation Best Practices

Proper installation maximizes your enclosure's protective capabilities. Use appropriate gaskets and sealants for outdoor applications, ensuring all penetrations maintain the specified IP rating. Indoor installations should prioritize accessibility and cable organization.

Create service loops in external cables to prevent water infiltration through capillary action. Position cable entries on the enclosure's bottom or sides rather than the top whenever possible. This simple step dramatically reduces water intrusion risk.

Sizing Guidelines for Common IoT Platforms

Raspberry Pi 4 projects require minimum internal dimensions of 95mm x 70mm x 30mm, but 120mm x 80mm x 40mm provides comfortable working space. Arduino-based projects often fit in smaller enclosures, typically 80mm x 60mm x 25mm or larger depending on shield requirements.

ESP32 and similar microcontroller boards work well in compact enclosures measuring 60mm x 40mm x 20mm or larger. Always account for antenna placement requirements, as metal enclosures can significantly reduce wireless performance.

Budget-Friendly Alternatives

Generic plastic project boxes offer significant cost savings for prototype work or non-critical applications. While these lack the refinement of name-brand enclosures, they provide adequate protection for many indoor IoT projects.

3D printing enables completely custom enclosures tailored to specific requirements. Modern filaments like PETG and ABS provide excellent durability and chemical resistance. Consider printing costs and time when evaluating this option against commercial alternatives.

Making Your Final Decision

The best small enclosures for IoT projects balance protection, accessibility, and cost while meeting your specific application requirements. Outdoor projects demand weatherproof construction and UV resistance, while indoor devices can prioritize aesthetics and easy access.

Consider your project's entire life cycle, from initial development through long-term deployment. An enclosure that accommodates future modifications and repairs will save time and money throughout your IoT device's operational life.

Investing in quality enclosures for IoT & Raspberry Pi, protects your electronics investment and ensures reliable operation. The small additional cost of a proper case pays dividends through reduced maintenance, improved reliability, and professional appearance that enhances user confidence in your IoT solution.